|

Introduction Introduction

|

-AFDEX(Adviser as Friend for Forging process Design Experts)is

General-purpose metal forming simulator.

-AFDEX can be applied not only to conventional Bulk metal forming processes

including forging, rolling, extrusion and drawing

but also new Creative bulk metal forming processes

that can be dvised by creative engineers or experts.

- AFDEX is theoretically based on rigid-themoviscoplastic

finite element method. It can solve the metal flow problem

and heat transfer in metal forming and die structural analysis problem.

|

Comparison of AFDEX 3D with AFDEX 2D Comparison of AFDEX 3D with AFDEX 2D

|

|

Theoretical background of 3D and 2D Theoretical background of 3D and 2D

| Item |

AFDEX 2D |

AFDEX 3D |

| Numerical method |

Rigid-Thermoviscoplastic Finite Element Method |

| Finite element |

Quadrilateral element, Conventional FEM |

Tetrahedral element, MINI-element FEM,Hexahedral element |

| Incompressibility condition |

Penalty method, Lagrange multiplier method |

Lagrange multiplier method |

| Linear equation |

Direct method |

Iterative method,Direct method |

| CAD I/F |

DXF file |

STL file |

| Friction |

Coulomb friction law,constant shear friction law |

|

Verification Verification

|

*Comparison of predictions with experiments

|

|

*Precision side bevel gear forging simulation

|

|

*Long shaft bevel gear forging simulation

|

|

*Tripod forging simulation

|

|

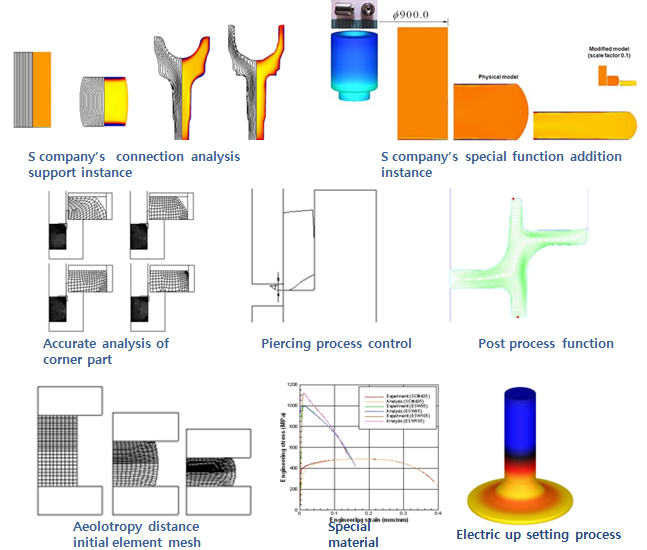

Various Solution Various Solution

|

|

Strength Of AFDEX Strength Of AFDEX

1.Comparison of the results

1-1.Rotor pole (warm) example1

|

|

1-2.example2

|

|

1-3.example3

|

|

1-4.example4

|

|

1-4.example5

|

|

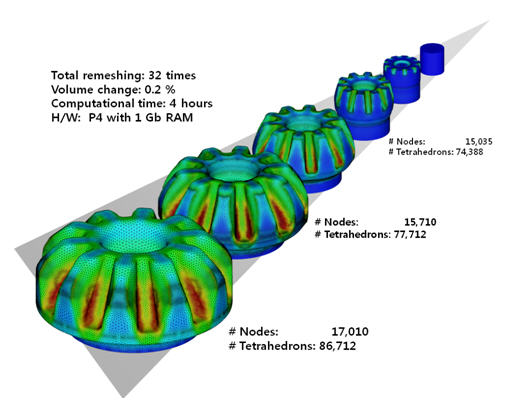

Adaptive remeshing function Adaptive remeshing function

|

*AFDEX 3D Considering contact boundary

|

*F S/W

|

Prompt technical support and responding based on the original domestic development software Prompt technical support and responding based on the original domestic development software

|

|

Close support of High-class technology by domestic developer Close support of High-class technology by domestic developer

-If training of AFDEX 2D and 3D is one day, it is sufficient. But the education of high-class application technology and technology with theory must be continued.

-Except developer, The technical instruction is difficult. But Cubictek provides continuous education and support.

-Customizing is easy because this software is domestic development software.

|

|

Collaboration application of university human, physical resourceClose support of High-class technology by domestic developer Collaboration application of university human, physical resourceClose support of High-class technology by domestic developer

-Field technology application through Metal formation field specialization;TIC

-Human resource training and related company distribution through academic-industrial cooperation R&D

|

|

|

Introduction |

|

The tendency toward various-item & small-lot production is arising in the manufacturing field.

Meanwhile, the number of highly skilled engineer is decreasing. In the global market, the major

factor for competitive power is the reduction of lead-time and cost. Reflecting these conditions, an intelligent forging simulator that improves the process design has been developed.

Therefore, AFDEX(Adviser for Forging Design EXpert ) is designed for Verification of Forging

process and Development of Forging Die. |

| |

|

Features |

|

| Accuracy |

|

-From over 500examples, which include not only simple upsetting processes but also complex multi-stage forging processes found from the hot, warm, cold forging industries, accuracy and capability have been verified. |

|

|

|

|

Suitable for Everyone

- AFDEX dose not enforce the related theory and FEM(Finite Element Method) on users?forging process design engineers. AFDEX has been developed under concept that even novices can use it with ease. |

|

|

| |

| Easy to USE |

|

-The wizard method of AFDEX and various examples help you analyze the forging process with ease. AFDEX has been never discouraged you at all. |

|

|

|

|

| Designed for PC Environment |

|

-AFDEX dose not require an expensive UNIX machine. This feature helps you apply AFDEX more conveniently. AFDEX is more stable than other systems that are downsized from UNIX to PC environment.

|

|

| |

| Various simulation Result |

|

-AFDEX shows following various results : Deformed shape, Nodal velocity, Strain, Strain-rate, Stress, Metal flow line, Metal point flow, Boundary nodal force, Interfacial stress, Temperature-distribution, Damage, Wear, Volume change, Load, Power, etc. |

| |

|

| |

|

|

| Automatic Analysis of Multi-Process |

| - |

The multi-stage forging processes can be simulated automatically without user interference. |

| |

|

| |

|

|

|

Analysis Examples |

|

| Process Design Evaluation |

|

-You can see whether material fills the die entirely or not.The multi-stage forging processes can be simulated automatically without user interference. |

| |

|

| |

|

|

|

|

System Requirements |

|

|

Minimum |

Recommendation |

| CPU |

Pentium Ⅲ |

Pentium Ⅳ |

| MEMORY |

64MB |

256MB |

| HDD |

300MB |

500MB |

| GRAPHIC |

1024X768 |

1024X768 |

| VRAM |

16MB |

64MB |

| OS |

Windows 98 /NT/2000/XP/Vista/Win7 |

|